Client Introduction

Lakshmi Card Clothing (LCC) has established itself as a major supplier of card clothing

products, both in India and globally, due to its consistent introduction of innovative

products to the industry. As a leading manufacturer of card clothing, card service

machines, stationary flats, flat tops, fillets, and other key accessories, LCC has

solidified its position as a top player in the card clothing industry.

Problem Statement

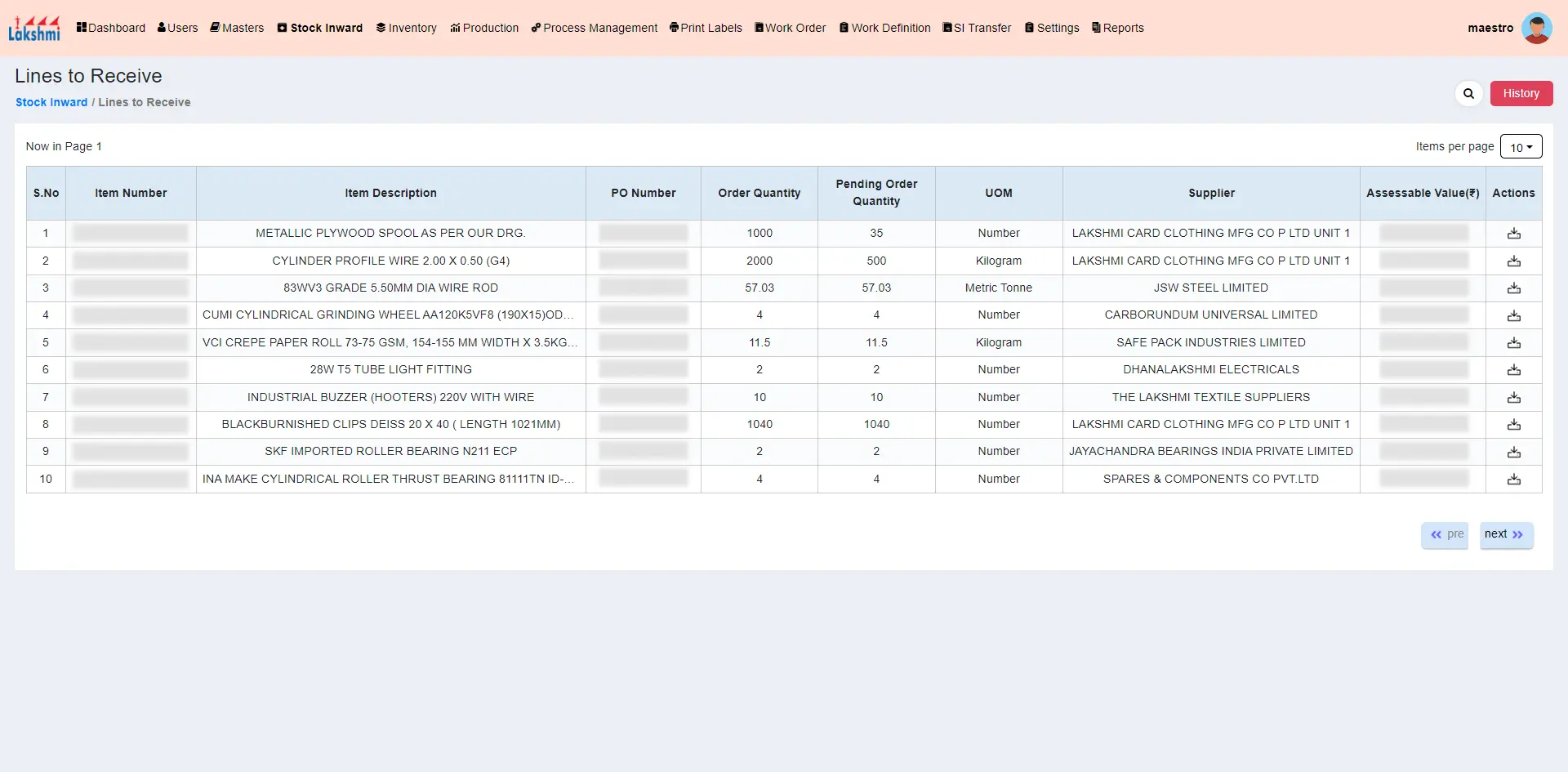

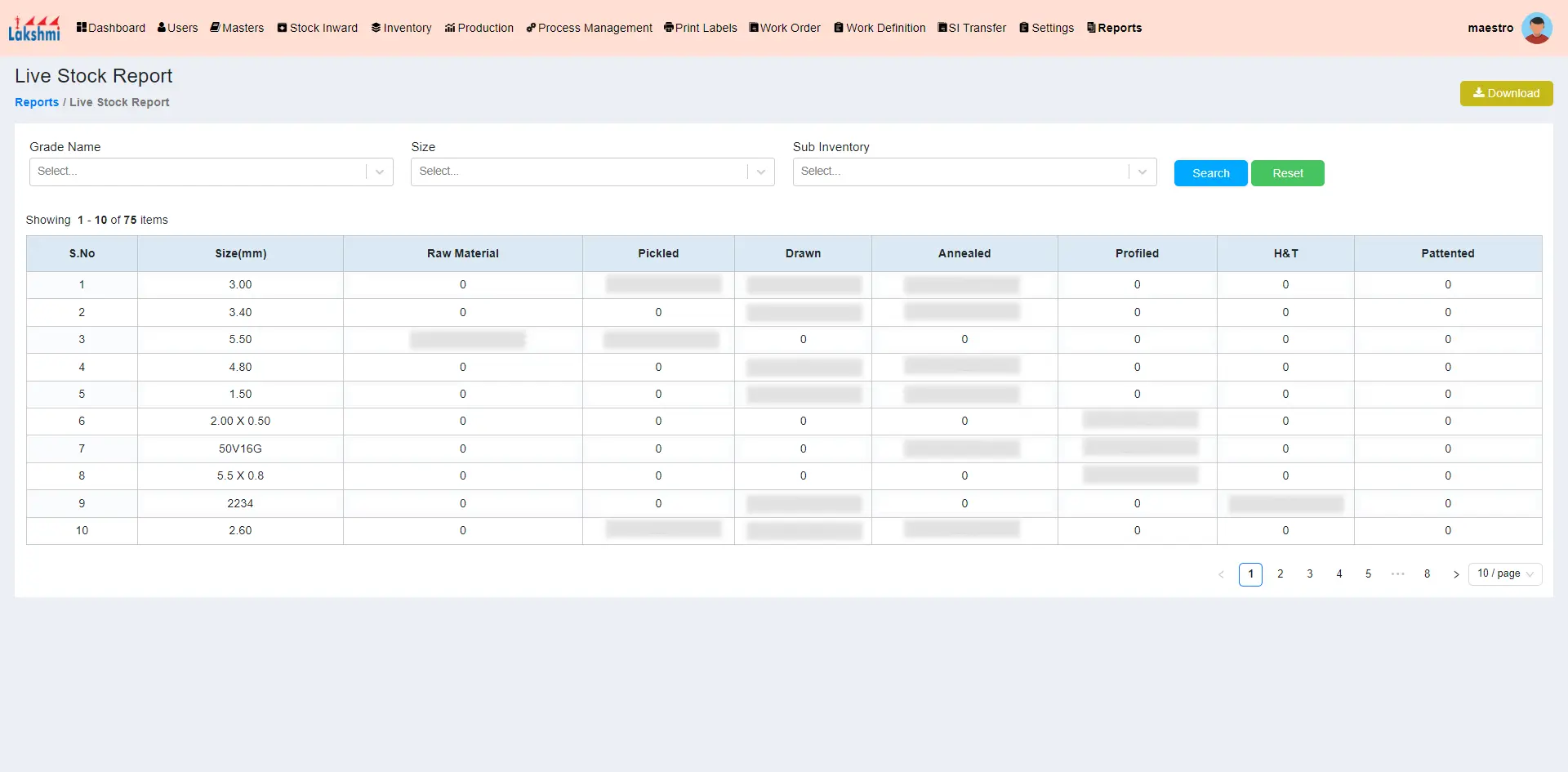

LCC faced multiple challenges in its production management, carrying out a wide range of

industrial processes, including pickling, drawing, annealing, profiling, hardening and

tempering, and patenting.

- Inefficient handling of raw materials leads to delays and errors.

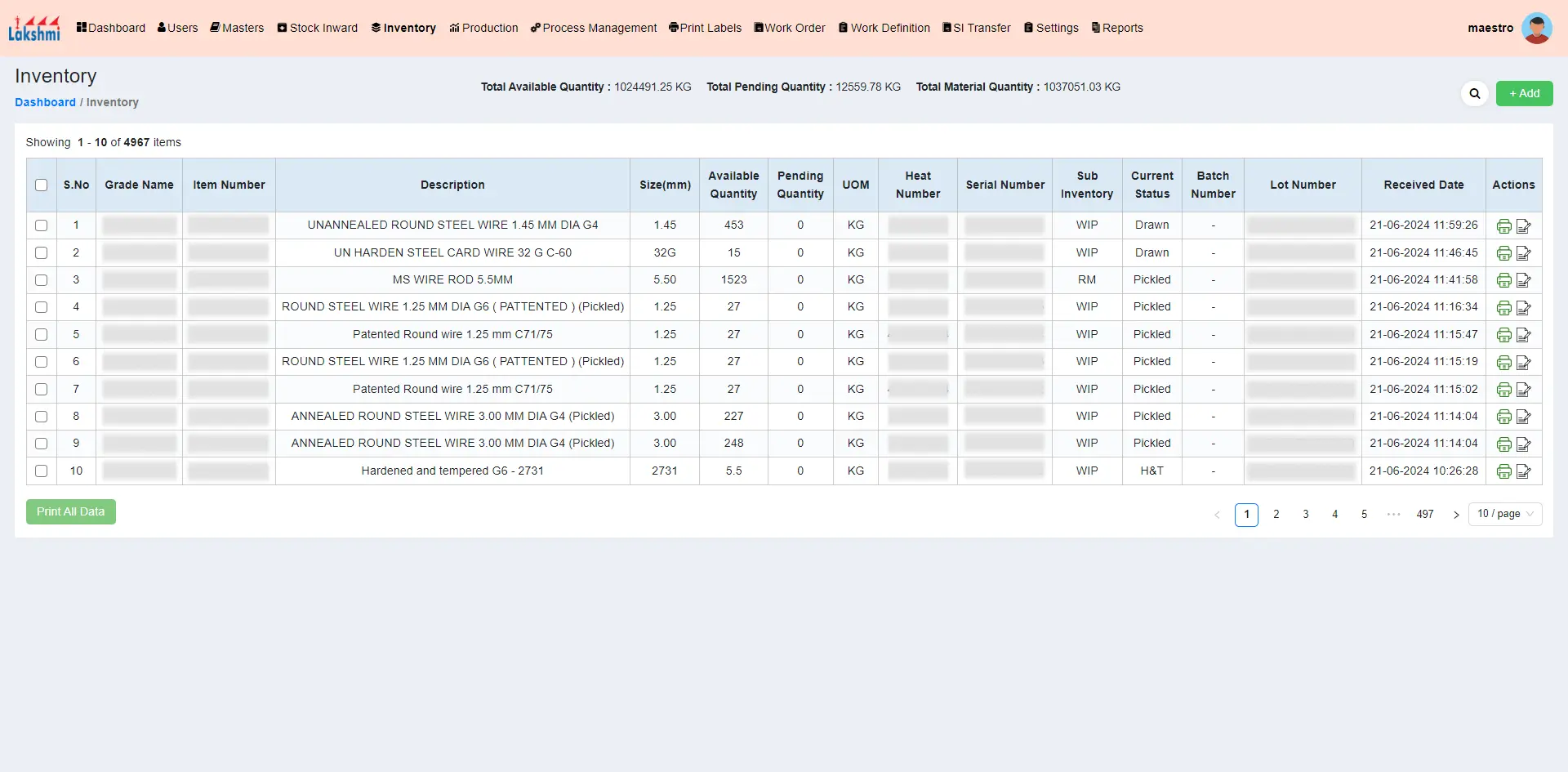

- A lack of real-time inventory tracking is causing differences.

- Manual entry errors affect the accuracy of production data.

- Difficulty in integrating with existing ERP systems like Oracle Fusion.

- Challenges in tracking the production process and ensuring quality control.

These issues highlighted the need for a robust and integrated solution to streamline

operations and enhance overall efficiency.

Solution

We developed a custom-built production management application designed to integrate

seamlessly with their Oracle Fusion ERP.

Key Features

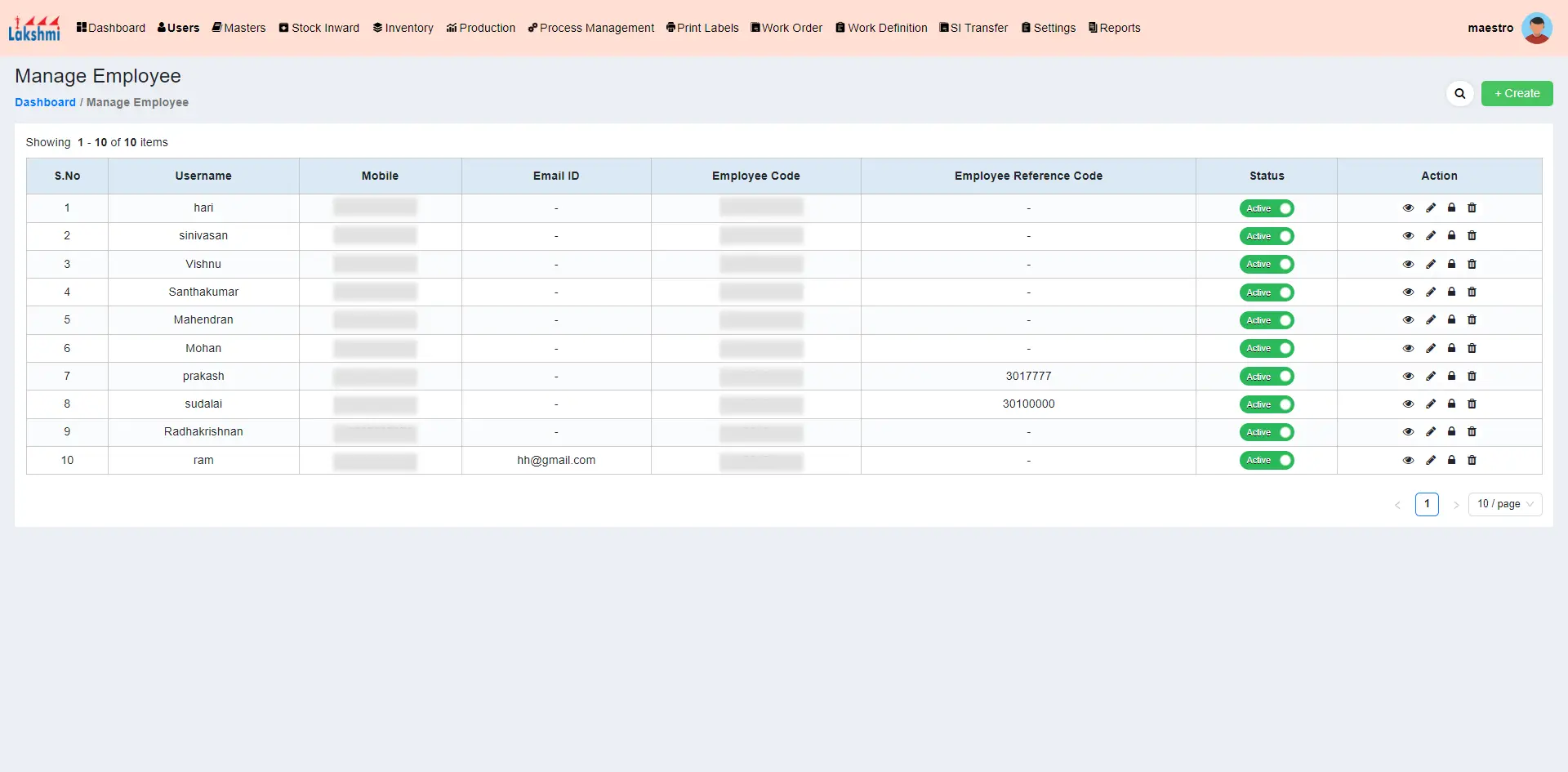

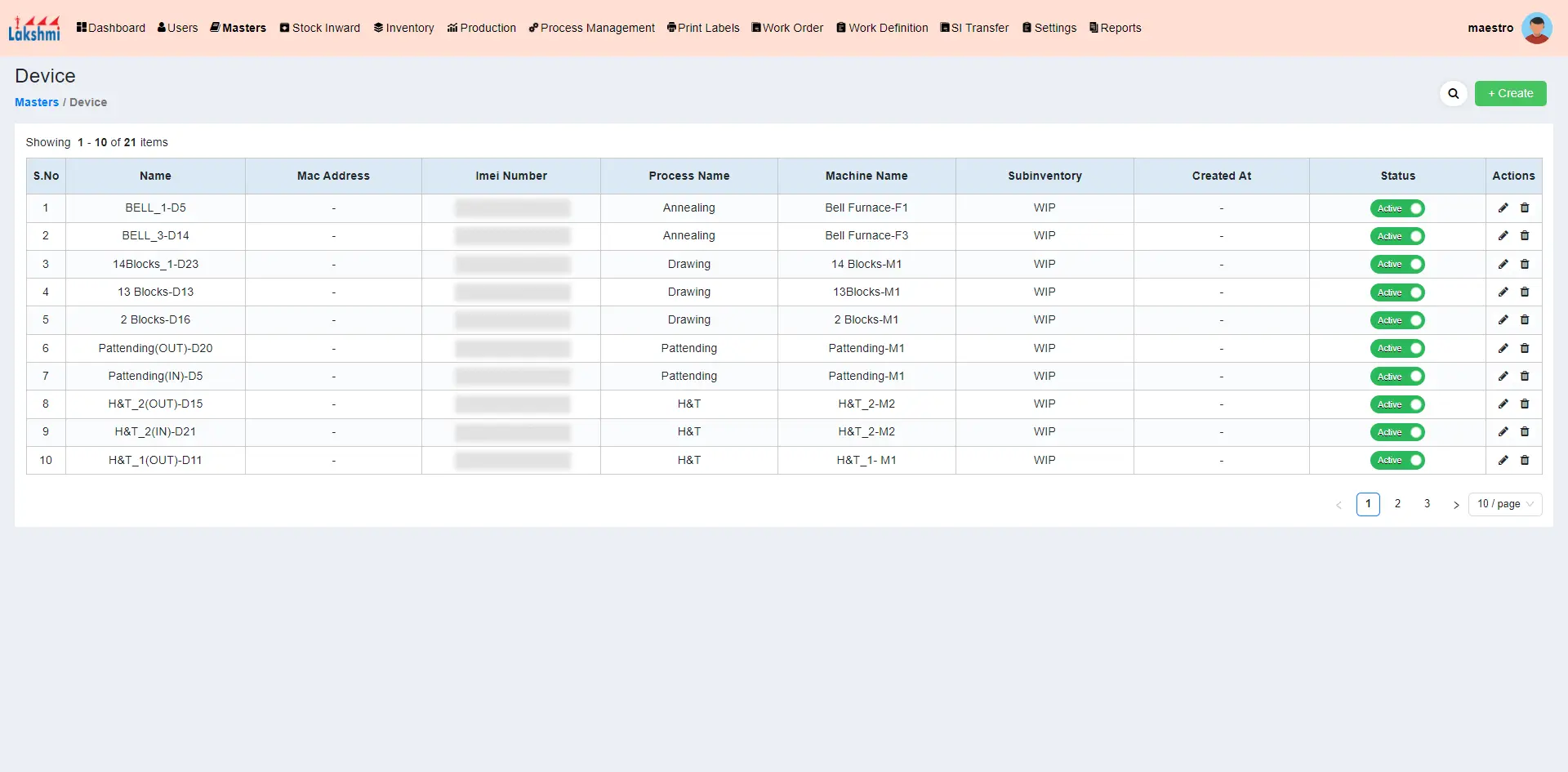

- User-Friendly Mobile Interface: Allows employees to manage inventory and

production processes efficiently using mobile devices.

- Automated Serial Number Generation: Ensures precise tracking of each coil

throughout the production process.

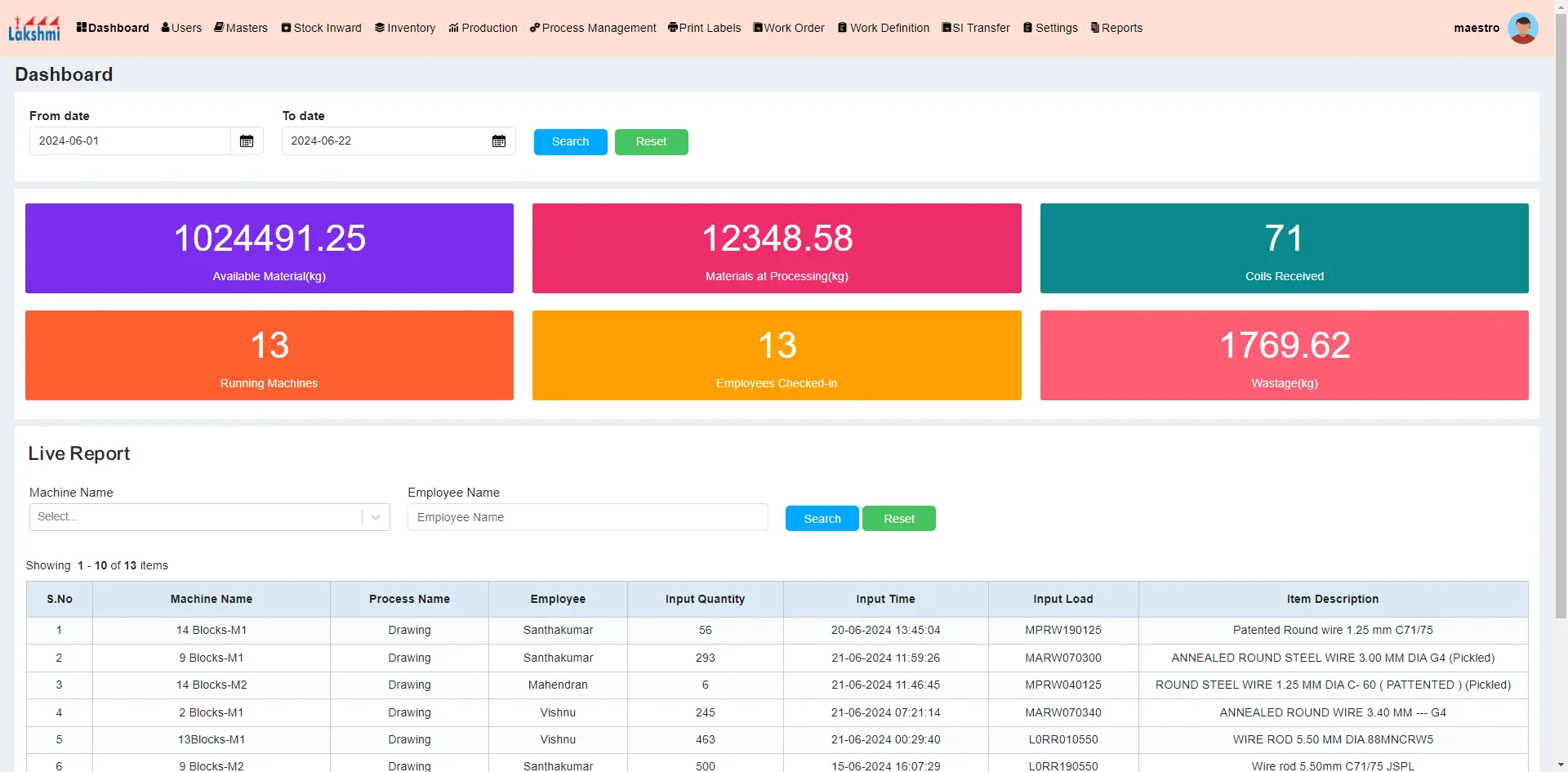

- Real-Time Inventory Management: Updates inventory status instantly, ensuring

accurate and up-to-date records.

- Weighing Scale Integration: Automates the capturing of coil weights, reducing

manual entry errors.

- Oracle Fusion Integration: Syncs production data with Oracle Fusion, ensuring

seamless data flow across business processes.

Results and Benefits

The deployment of the Production Management ERP Addon system brought significant

improvements to LCC's operations:

- Efficiency: Manual inventory tasks were reduced, allowing employees to focus

on more critical activities.

- Accuracy: Production accuracy was improved due to automated tracking and

real-time updates.

- Productivity: Overall operational efficiency was increased, leading to faster

production cycles and reduced downtime.

- Quality Control: Enhanced tracking and reporting mechanisms ensured

consistent quality across all production processes.

- Cost Savings: Optimized resource utilization and reduced manual errors

resulted in substantial cost savings.

Conclusion

By addressing critical production management challenges with a tailored solution, LCC was

able to upscale its operations, achieve business excellence, and set a benchmark in the

textile industry.

This was accomplished through advanced technology solutions that tracked the company's

complete production process from raw material to finished commodity and significantly

reduced waste.