Our Studies

Upgrading Service Request Operations using a Custom ERP at Lakshmi Card Clothing (LCC)

Lakshmi Card Clothing (LCC) is a leading provider of card clothing solutions for the textile industry.

Lakshmi Card Clothing (LCC) is a leading provider of card clothing solutions for the textile industry.

Lakshmi Card Clothing (LCC) has established itself as a significant supplier of card clothing products, both in India and globally, due to its consistent introduction of innovative products to the industry. As a leading manufacturer of card clothing, card service machines, stationary flats, flat tops, fillets, and other key accessories, LCC has solidified its position as a top player in the card clothing industry.

LCC faced several operational challenges in managing the service requests from their service engineers spread across India, including:

The above challenges posed a decrease in efficiency and customer satisfaction, necessitating a streamlined solution to optimize their service operations.

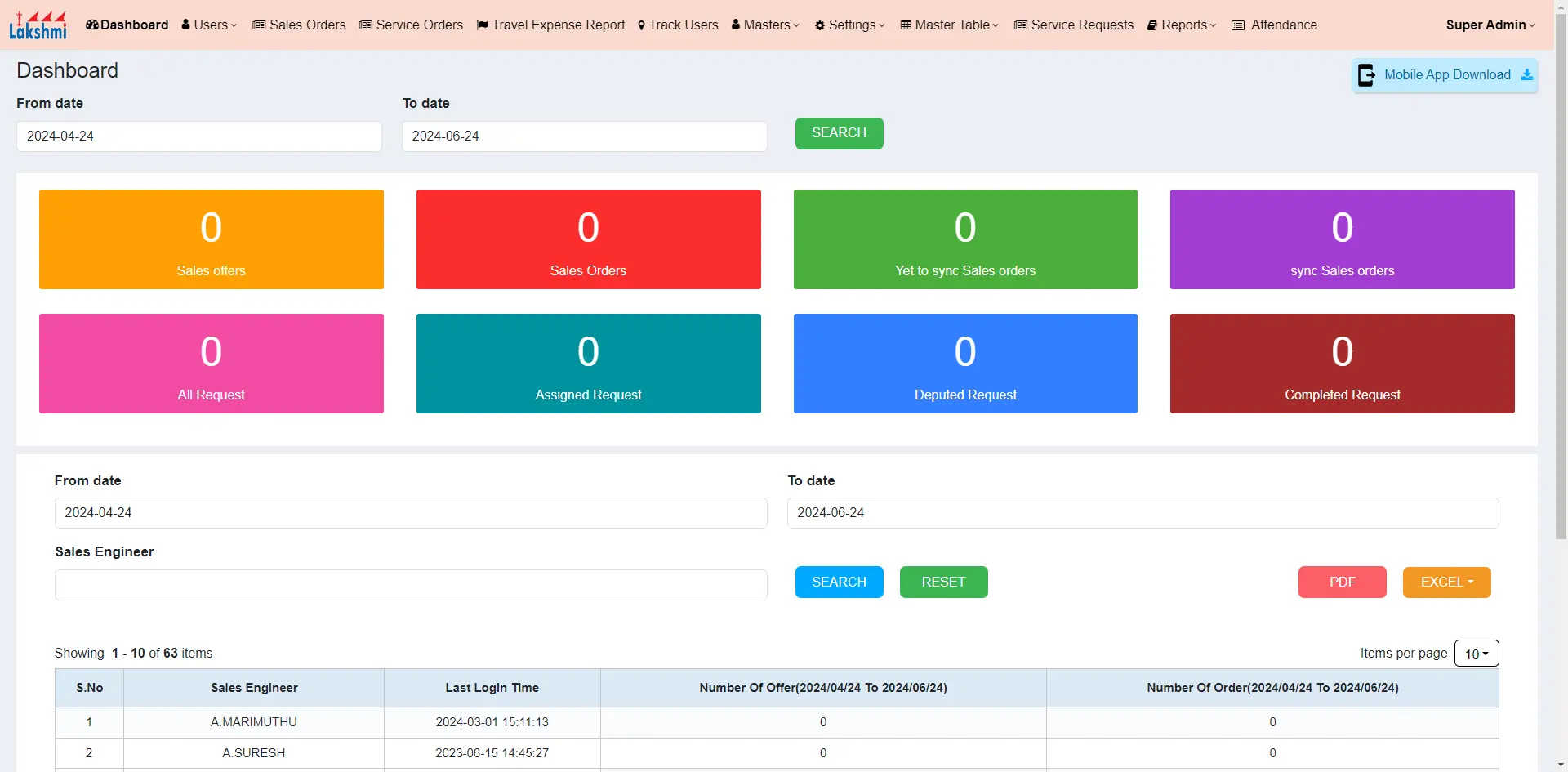

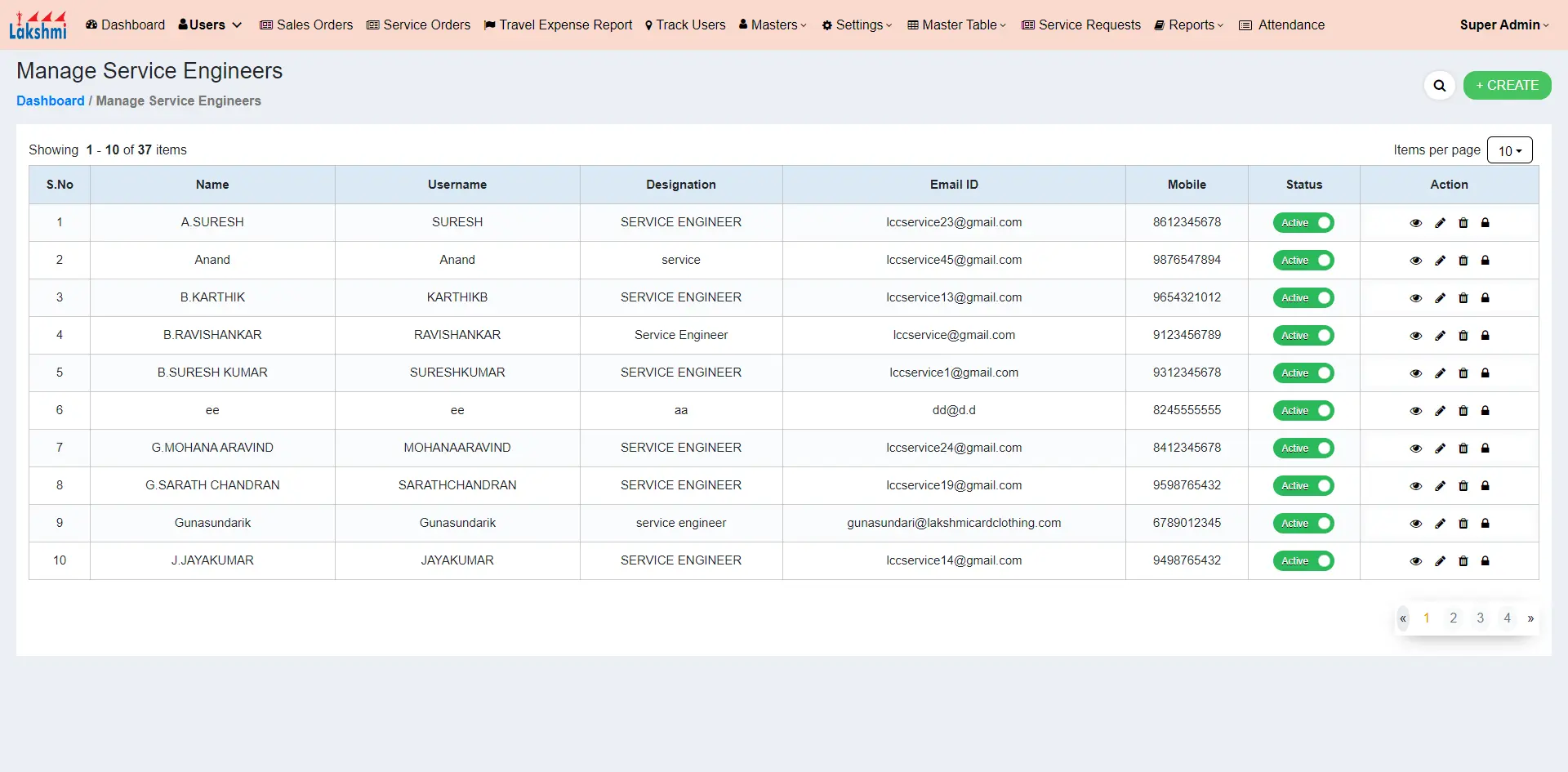

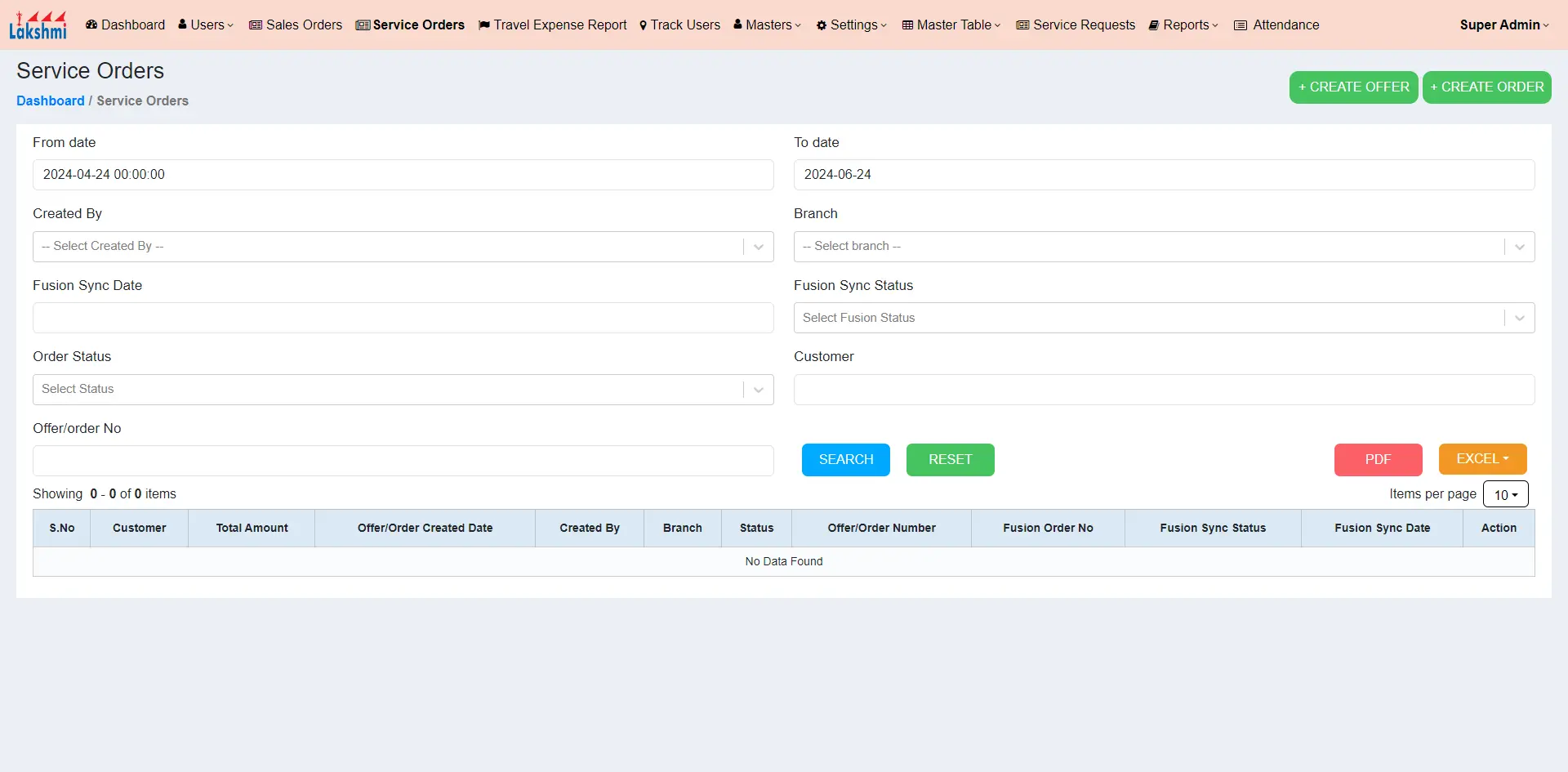

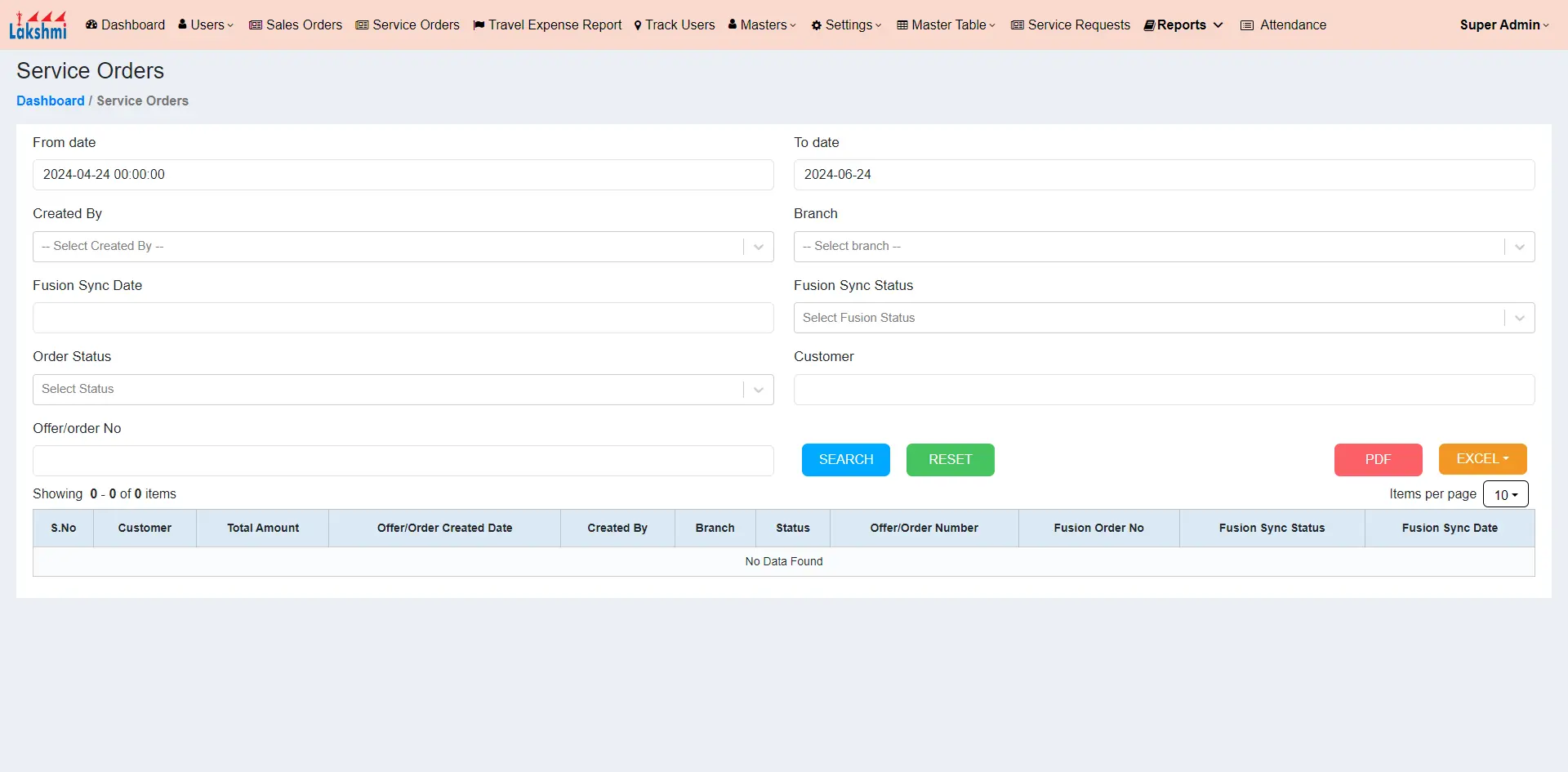

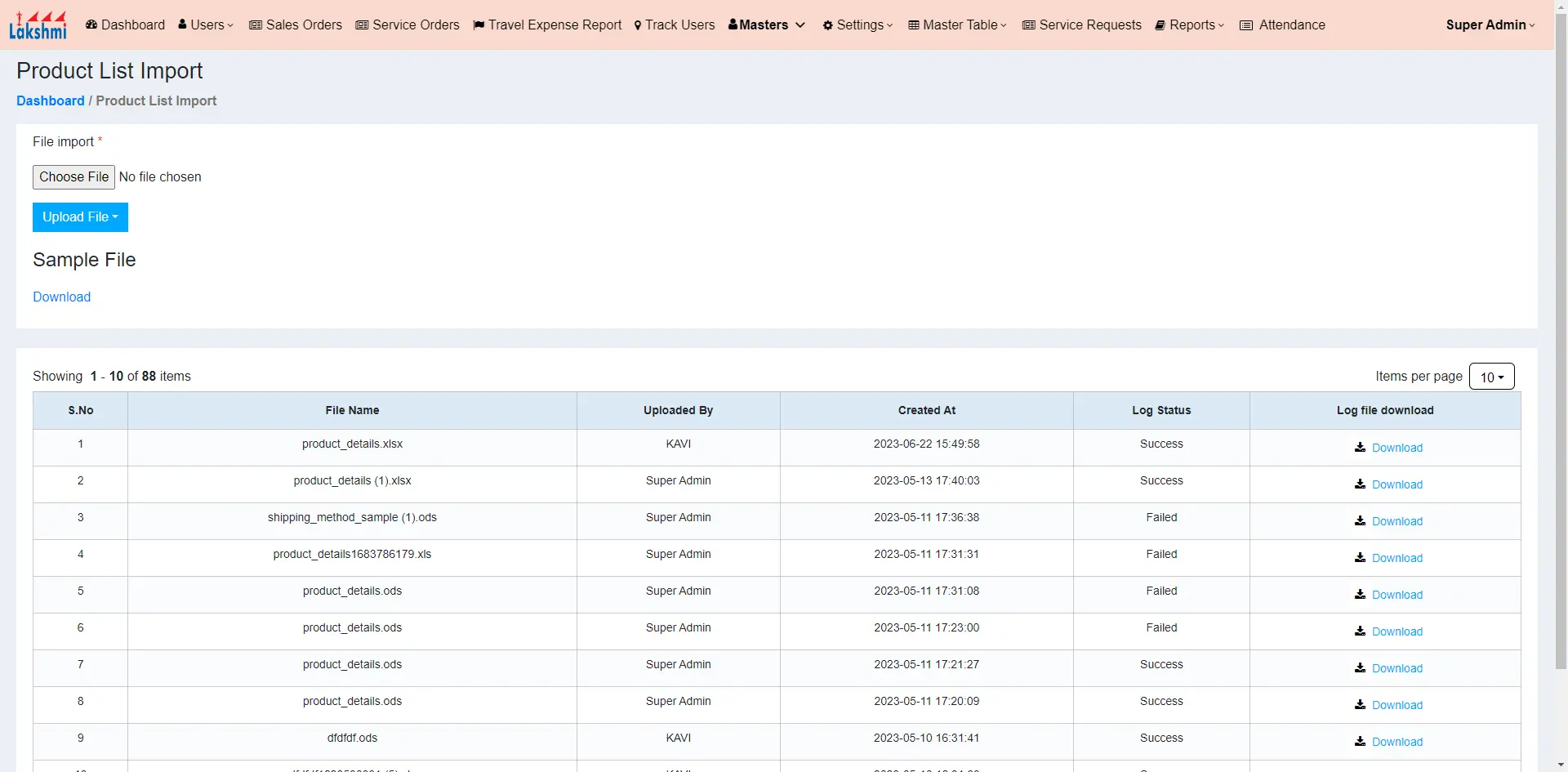

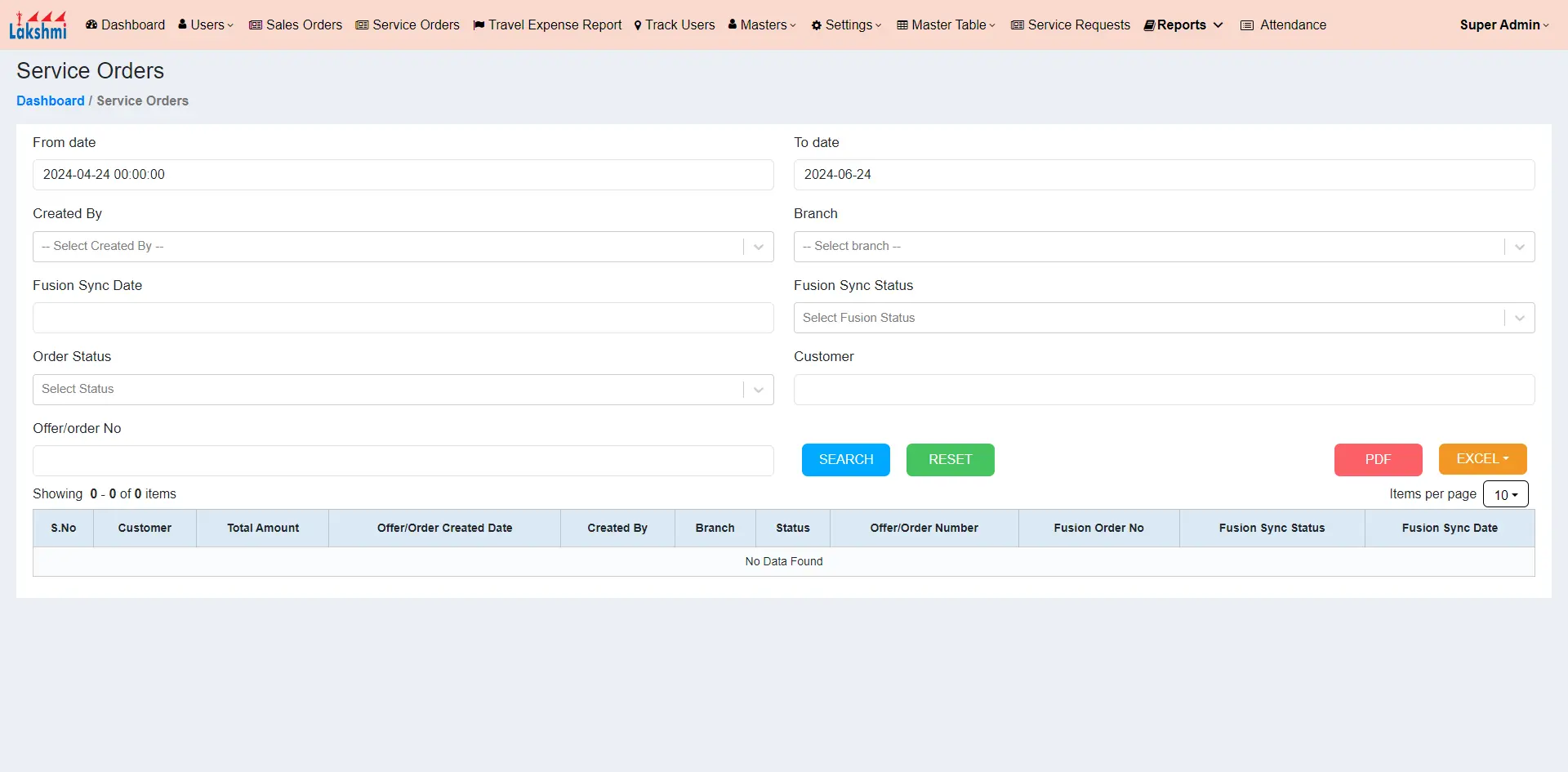

We developed a custom-built Service Order Management application designed to integrate seamlessly with their Oracle Fusion ERP.

The application was developed focusing on three key roles:

The introduction of the custom Service Management ERP with intuitive UI/UX led to significant improvements:

"The custom ERP Addon has revolutionized our service management operations. The efficiency and reliability improvements are remarkable, and our customers have noticed the difference," says LCC.

LCC recommends such custom ERP addons to any service-oriented business looking to enhance its operational efficiency and increase the ERP adoption within the organization.