Unlock Seamless Data Flow: Embracing the Unified Namespace Architecture

In today's dynamic manufacturing landscape, data is the lifeblood of efficiency, agility,

and innovation. However, the reality for many manufacturers is a fragmented data

landscape – disparate systems, isolated silos, and a constant struggle to gain a

holistic view of their operations. Enter the Unified Namespace (UNS), an architectural

pattern that promises to break down these barriers and usher in an era of seamless data

flow.

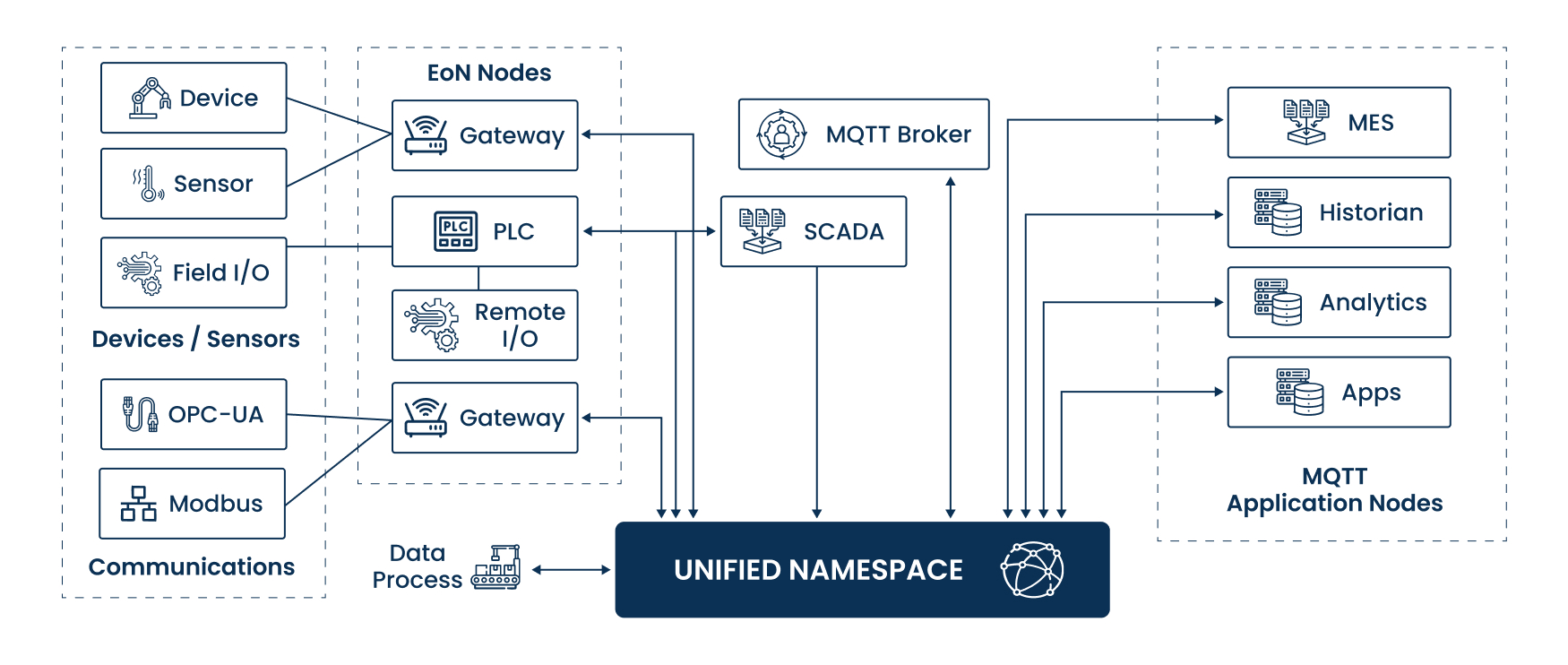

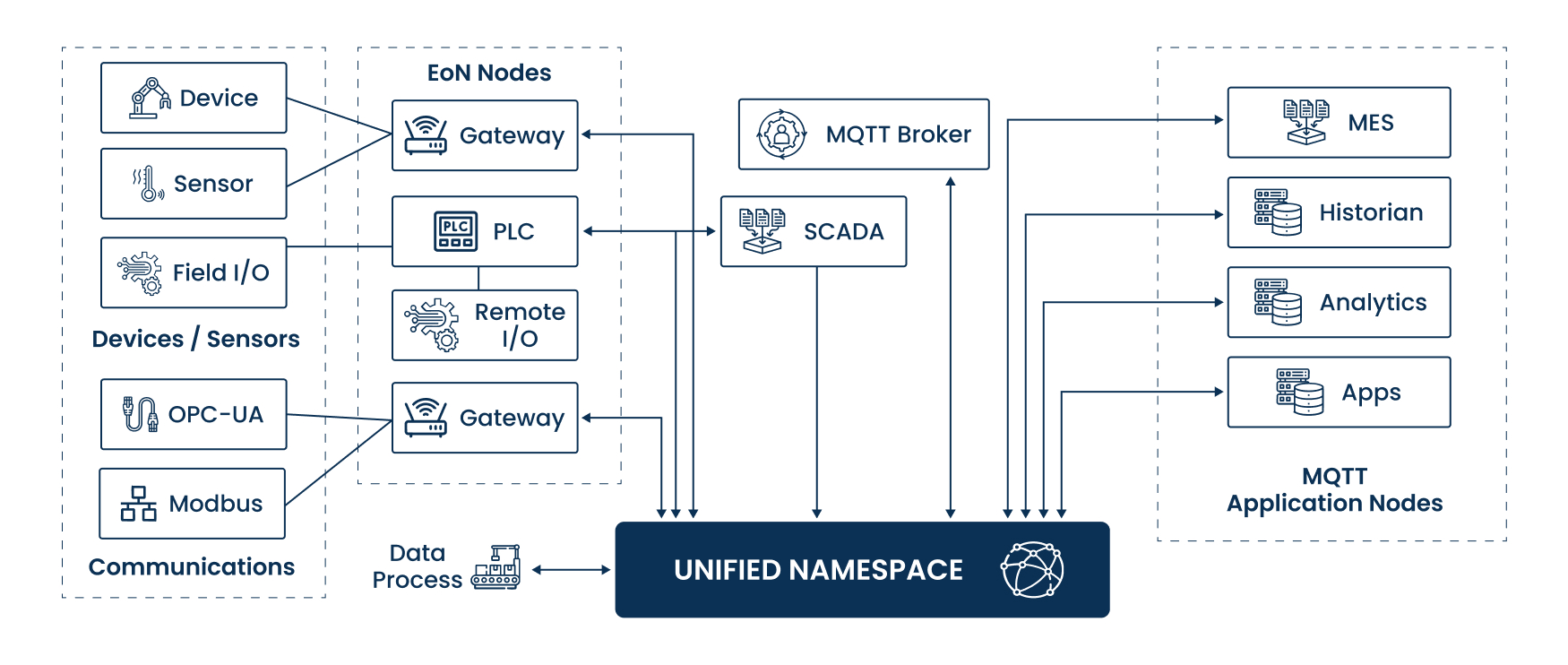

Imagine a central nervous system for your entire manufacturing operation. That's

essentially what a Unified Namespace provides – a single, logical, and hierarchical

structure that organizes all your operational data, from the shop floor to the

enterprise level. Instead of applications directly communicating with individual devices

and systems, they interact with this central namespace, subscribing to the data they

need and publishing the data they generate.

The Compelling Advantages of a Unified Namespace

Adopting a Unified Namespace offers a wealth of benefits for manufacturing industries:

- Enhanced Data Visibility and Context: By centralizing data and providing a

consistent naming convention, a UNS offers unparalleled visibility into your entire

operation. You gain a holistic understanding of production processes, asset

performance, quality control, and more, all within a unified context. This empowers

better decision-making and faster problem-solving.

- Simplified Integration and Interoperability: Say goodbye to complex

point-to-point

integrations! A UNS acts as a decoupling layer, making it significantly easier to

integrate new systems and applications. Different technologies and protocols can

seamlessly exchange information through the central namespace, fostering greater

interoperability.

- Improved Scalability and Flexibility: As your manufacturing operations evolve

and

grow, a UNS provides a flexible and scalable foundation. Adding new devices,

machines, or systems becomes a much simpler process, as they only need to interact

with the central namespace.

-

Real-time Data Availability for Analytics and Insights: With all critical

data

readily available in a structured format, leveraging advanced analytics, AI, and

machine learning becomes significantly easier. Real-time insights can be derived to

optimize processes, predict maintenance needs, improve quality, and drive continuous

improvement.

-

Empowered Edge Computing: A UNS facilitates the deployment of edge computing

solutions. Data can be processed closer to the source, and only relevant information

is published to the central namespace, reducing network latency and improving

real-time control.

Navigating the Challenges of UNS Adoption in Manufacturing

While the benefits are clear, adopting a Unified Namespace in manufacturing isn't without

its challenges:

- Legacy System Integration: Many manufacturing facilities have a significant

installed base of legacy equipment and systems that may not readily support modern

communication protocols or easily integrate with a UNS.

- Data Governance and Standardization: Establishing consistent data naming

conventions, data quality standards, and robust governance policies across diverse

operational technology (OT) and information technology (IT) systems can be a complex

undertaking.

- Security Considerations: Centralizing data in a UNS requires careful

consideration

of security implications. Robust cybersecurity measures are crucial to protect

sensitive operational data from unauthorized access and cyber threats.

- Skills Gap and Training: Implementing and managing a UNS requires a skilled

workforce with expertise in both OT and IT domains. Addressing the potential skills

gap through training and development is essential.

- Organizational Culture and Collaboration: Successful UNS adoption requires

strong

collaboration between OT and IT teams, which may have historically operated in

silos. Fostering a culture of data sharing and collaboration is critical.

Guidelines to Overcome Adoption Challenges

Here's a roadmap to navigate these challenges and successfully implement a Unified

Namespace:

- Start with a Phased Approach: Instead of a big-bang implementation, begin

with a

pilot project in a specific area of your manufacturing operation. This allows you to

learn, refine your approach, and demonstrate the value of the UNS before a

full-scale deployment.

- Prioritize Data Governance: Establish clear data ownership, naming

conventions, data

quality standards, and access control policies from the outset. Involve both OT and

IT stakeholders in defining these guidelines.

- Focus on Secure Integration: Implement robust security measures at every

layer of

the UNS architecture, including network segmentation, access controls, encryption,

and continuous monitoring.

- Invest in Training and Upskilling: Provide comprehensive training to your OT

and

IT teams on the principles, technologies, and best practices associated with the

Unified Namespace. Consider bringing in external expertise to support the initial

implementation.

- Foster OT/IT Collaboration: Establish clear communication channels and

collaborative workflows between OT and IT teams. Encourage cross-functional teams to

work together on the UNS implementation and ongoing management.

- Choose the Right Technology: Select technologies and protocols that align

with

your existing infrastructure and future needs. Consider open standards and widely

adopted protocols to ensure interoperability.

The Pivotal Role of MQTT

MQTT (Message Queuing Telemetry Transport) plays a significant role in enabling the

Unified Namespace architecture, particularly in industrial environments. Its lightweight

nature, publish/subscribe messaging model, and efficient handling of intermittent

connections make it ideal for connecting a wide range of industrial devices and sensors.

Importance of MQTT in UNS:

- Efficient Data Transmission: MQTT's low bandwidth consumption and efficient

message

handling make it well-suited for transmitting data from resource-constrained devices

over potentially unreliable industrial networks.

- Decoupled Communication: The publish/subscribe model decouples data producers

from

consumers. Devices publish data to specific topics within the UNS, and applications

subscribe to the topics they are interested in, without needing direct knowledge of

each other.

- Scalability and Flexibility: MQTT's architecture can easily scale to

accommodate a

large number of devices and applications. Adding new data sources or consumers is

straightforward.

- Real-time Data Availability: MQTT facilitates the near real-time transmission

of

operational data to the UNS, enabling timely insights and responsive control

actions.

Maestro: Your Partner in Unified Namespace Adoption

At Maestro, we understand the transformative potential of the Unified Namespace for

manufacturing industries. Our team of experienced OT and IT professionals possesses the

deep expertise to guide you through every step of your UNS journey.

We can help you with:

- Assessment and Strategy: Evaluating your current infrastructure and

developing a

tailored UNS adoption strategy aligned with your business goals.

- Architecture and Design: Designing a robust and scalable Unified Namespace

architecture that meets your specific requirements.

- Implementation and Integration: Seamlessly integrating your existing systems

and

deploying the necessary technologies.

- Data Governance and Security: Establishing best practices for data governance

and

implementing comprehensive security measures.

- Training and Support: Empowering your team with the knowledge and skills to

manage

and maintain your Unified Namespace.

Ready to unlock the power of seamless data flow and transform your manufacturing

operations?

Contact Maestro today to explore how a Unified Namespace

architecture can

drive efficiency, innovation, and growth for your business. Let us be your trusted

partner in building a connected and intelligent manufacturing future.